As the use of pure electric vehicles becomes more and more widespread and the demand for charging grows, the market puts forward higher and higher requirements for the safety and convenience of vehicle charging. Convenient, safe and fast charging is the unanimous demand of the market for vehicles. This post focus on AC charging system.

The charging of electric vehicles can only be DC, while the national general power supply are AC, in order to solve the problem of AC to DC charging, there needs to be a conversion method.

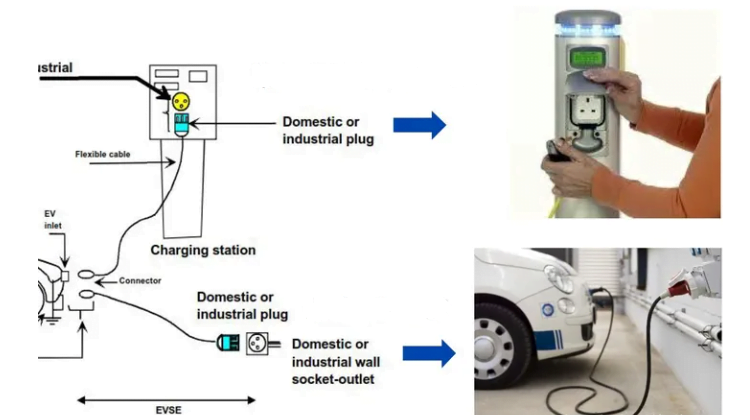

AC charging means that the voltage input to the vehicle from the power grid is AC, either 220V AC one-way or 380V AC three-phase. The AC power passes through the standard charging plug and charging socket, and enters the on-board charger, which then converts the AC power into DC power to charge the power battery, completing the basic AC charging.

Composition of AC charging system

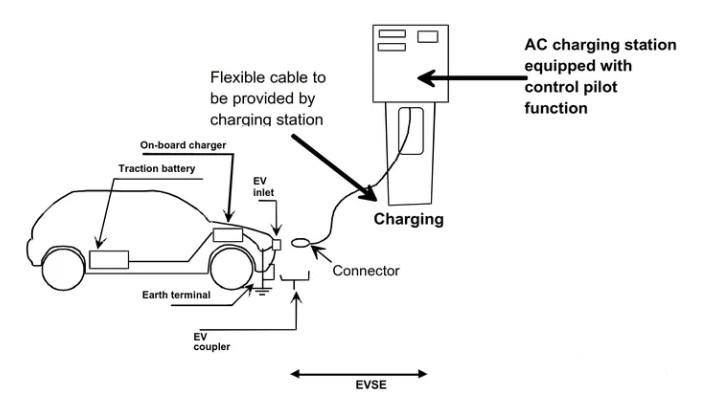

The components of AC charging are mainly composed of vehicle chargers, AC charging sockets (AC charging socket harnesses), charging cables, AC charging piles or 220V AC power supplies and vehicle controllers (VCU, BMS).

In which the AC charging socket and on-board charger are fixed on the vehicle, the portable charger also put in the boot, and the AC charging station is fixed in the car park.

The function of Station, portable charger, on-board charger, sockets.

(1) The on-board charger is the key component of the AC charging system, which converts AC power into DC power to charge the battery according to the control instructions.

(2) The AC charging socket is a IEC62196-2 standard part, which is the interface of the vehicle connecting to the external power grid, and its interface has two signal circuits, one grounding circuit, one zero wire circuit and three fire wire circuits, with a total of seven interfaces, and the corresponding fire wire interface is applied according to the input voltage of 220V AC or 380V AC.

(3) Vehicle controller is implemented to monitor the state of the vehicle and issue control instructions to the on-board charger to make it work or stop working, control its working current and voltage, etc. It is the control brain of vehicle charging.

(4) Mode 2 charging cable is the charging cable that connects the external power grid and the vehicle, and directly provides 220V AC power to the on-board charger. The function box on the cable can detect the vehicle and power grid status, connect or disconnect the power supply to the vehicle, with certain protection functions. According to the standard requirement, the 16A charger input charging current is limited to 13A, and the input voltage is 220V AC, so when charging with the charging cable of mode 2, the maximum input power of the on-board charger is 2,860W, which means that the charging time will be prolonged.

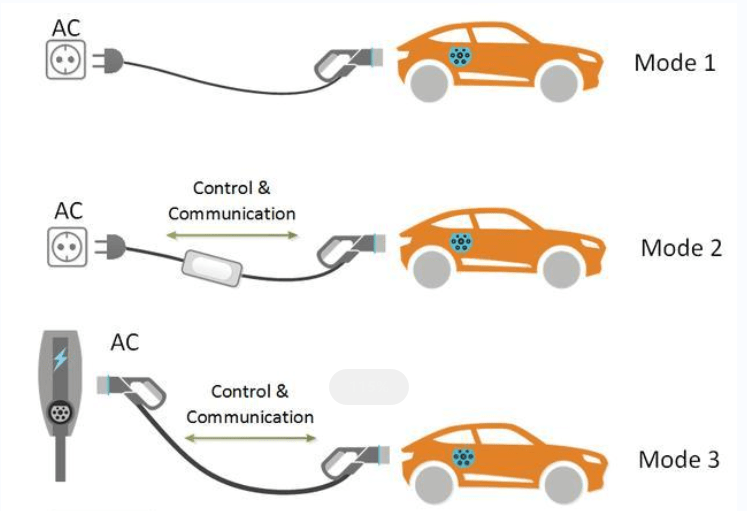

(5) The AC charging post is also a component of the vehicle that connects to the external power grid and directly provides 220V AC or 380V AC power to the on-board charger. It also has the function of detecting the state of the vehicle and the power grid, and connecting or disconnecting the power supply to the vehicle. The supply voltage of the charging post is 220V AC and 380V AC, depending on the output power of the charging post. According to the standard requirements, if the output current of the AC charging post is greater than 32 A, the supply voltage must be 380 V AC. Therefore, when charging with an AC charging post, the charging power is greater, i.e. the charging time will be shorter.

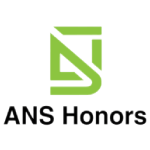

Three modes of AC charging

AC charging mode has a total of three charging modes, respectively, mode 1, mode 2 and mode 3. according to the standard requirements and charging safety, of which mode 1 has been used very little, mode 3 is generally used to connect the mode of mode C, its mode 2 and mode 3 connected to the AC charging principle of operation of the mode of C electrical diagrams as shown in Figure 2 and Figure 3.

1.Model 1 charging.

There is no control box on the charging gun, and the car is charged directly through the cable of the charging gun plugged into a household AC outlet for charging, which is unable to establish communication with the vehicle, and it is not possible to confirm the maximum current strength, voltage, and temperature when charging. Mode 1 charging method has basically been eliminated because of poor safety.

Although mode 1 does not need to transform the existing civil power distribution network, convenient and flexible, but a large number of electric vehicles connected to the grid charging will significantly increase the load on the grid, the impact of grid stability, and cause fire and other potential hazards, many countries directly prohibit mode 1 charging (such as the United States, the United Kingdom, Singapore), or set the upper limit of the charging current or charging time, and other additional limitations (such as France, Denmark and other continental European countries).

2.Model 2 charging

The mode 2 chargers assembly is equipped with a standard plug at one end, which is inserted into a standard socket to connect to the AC power network, and a connector at the other end of the charging cable assembly (vehicle end), with an in-line charging control box (IC-CPD or ICCB) in the middle of the cable assembly.

The in-circuit control box has a control guidance function according to IEC 61851 and meets the electrical protection requirements of IEC 62752.

Mode 2 chargers assembly needs to have control guidance function and provide protective grounding, at least three auxiliary wires are required, so the current mainstream several standard single-phase AC charging port are at least 5 holes (two holes for charging wire, two holes to provide control guidance, one hole grounding protection), three-phase AC charging port is generally 7 holes (four holes for the three-phase four-wire charging wire, two holes to provide control guidance, one hole grounding protection). protection). In many areas where three-phase and single-phase charging ports are common, seven holes are used, and two holes are not used for single-phase charging.

The charging parameters specified in IEC 61851-1 may not exceed.

32A/250V, AC single-phase

32A/480V, AC three-phase

3.Mode 3 charging

The difference between mode 3 and modes 1 and 2 is that the charging gun is not connected to the domestic AC grid, but to a dedicated AC power supply, i.e. an AC charging post. In this case, the charging gun can be used without an adapter, as the AC charging post itself acts as a protection device. Mode 3 ensures safe charging and also increases the charging speed to a certain extent (10/13/32A).

The AC charging port on the vehicle side of the Mode 3 charging post is the same as Mode 2. Consumers typically need to bring their own Mode 3 cable to use public AC charging stations.

After exploring the three modes of AC charging, it’s clear that the market offers a diverse range of AC chargers, each designed to meet different needs and scenarios. The key takeaway is the importance of selecting the most suitable charger for your specific requirements. With the vast array of options available, focusing on compatibility, charging speed, and the specific needs of your electric vehicle will ensure you make the most informed and effective choice.

Remember, the right charger not only enhances your charging experience but also maximizes the efficiency and longevity of your EV’s battery. Choose wisely to ensure you benefit from the full potential of electric mobility.