One solution for building charging stations

When it comes to constructing a charging station, there’s a multitude of essential components required to ensure its functionality and efficiency. Our company specializes in providing a diverse range of these crucial components, catering to the intricate needs of charging station construction projects.

From power distribution units to connectors, cables, mounting hardware, and safety features, we offer a comprehensive selection of high-quality components that are vital for the successful setup and operation of charging stations. With our expertise and dedication to delivering top-notch products, we strive to support the advancement of electric vehicle infrastructure by supplying the essential building blocks necessary for the seamless integration of charging stations into various environments.

As electric vehicles continue to revolutionize the automotive industry, the demand for efficient and reliable charging solutions has never been higher. At Honors EV company, we understand the pivotal role that charging accessories play in optimizing the EV charging experience.

From cables to adapters, connectors to mounts, our comprehensive range of accessories is designed to complement and enhance the functionality of your charging station. Explore our selection and discover how our accessories can elevate your charging infrastructure to new heights of convenience and efficiency.

A Type 2 socket for a charging station, also known as a Mennekes socket after its German inventor, is a standardized connector used in electric vehicle (EV) charging infrastructure, primarily in Europe. It’s designed for AC charging and is the most common standard for EVs and charging stations in European countries, but it’s also found in other parts of the world.

The Type 2 socket supports single-phase and three-phase power supply, allowing for a wide range of charging speeds. The charging capability can vary from the basic 3.6 kW (which might use a single-phase 16A supply) up to 43 kW (using a three-phase 63A supply), though the most common configurations for public and home charging points are 7 kW, 11 kW, and 22 kW. This flexibility makes the Type 2 socket suitable for a variety of settings, from private homes to public charging stations.

EVs equipped with a Type 2 inlet can use a Type 2 to Type 2 cable to connect to these sockets. The design of the Type 2 socket includes features for safety and security, such as pins for power, communication, and grounding, ensuring safe charging sessions. Its widespread adoption is partly due to its compatibility with a wide range of EVs and plug-in hybrid electric vehicles (PHEVs), making it a cornerstone of the EV charging infrastructure in regions where it’s standardized.

Introducing our cutting-edge cable management solutions designed specifically for charging stations. Our range of cable fixing brackets provides a reliable and robust method for securing charging cables, preventing tangling and tripping hazards while optimizing space utilization. Explore our selection of cable fixing brackets and revolutionize the way you manage charging cables at your charging station.

Introducing our advanced charging modules tailored for electric vehicle charging stations. Engineered with precision and innovation, our charging modules are designed to deliver optimal performance and reliability in every charging session. With features such as intelligent charging algorithms, temperature regulation, and compatibility with various charging standards, our modules ensure fast, safe, and efficient charging for all types of electric vehicles. Experience seamless integration and superior functionality with our state-of-the-art charging modules, setting new standards in EV charging technology.

Charging module is used in DC charging equipment, the main role is to convert the AC power in the grid into DC power for charging the power battery of new energy vehicles. The performance of charging module directly affects the overall charging efficiency of DC charging equipment, and at the same time, it is related to charging safety and other issues, it is the core component of DC charging equipment for new energy vehicles, and it is known as the “heart” of DC charging equipment; from the point of view of cost, the charging module can account for up to 50% of the cost in DC charging pile.

The mainly module include 20kW, 30kW, 40kW, exactly how to choose the assembly module depends on the charging pile, how much space, how to allocate the charging power as well as the convenience of maintenance in the later stage, for example, if we want to build a 120kW charging pile with double guns, we generally choose six 20kW modules stacked so that the average charging and rotating charging can be fully realised, and if we want to build a 60kW charging pile with only one gun, then we can choose a 40kw and 20kW stacked so that the cost is lower and the assembly is also more convenient.

The charging module communicates with the main monitoring through the CAN bus, and realizes the parameter setting of the charging module through the communication with the main monitoring, collects the operating parameters of the charging module, and controls the working state of the charging module.

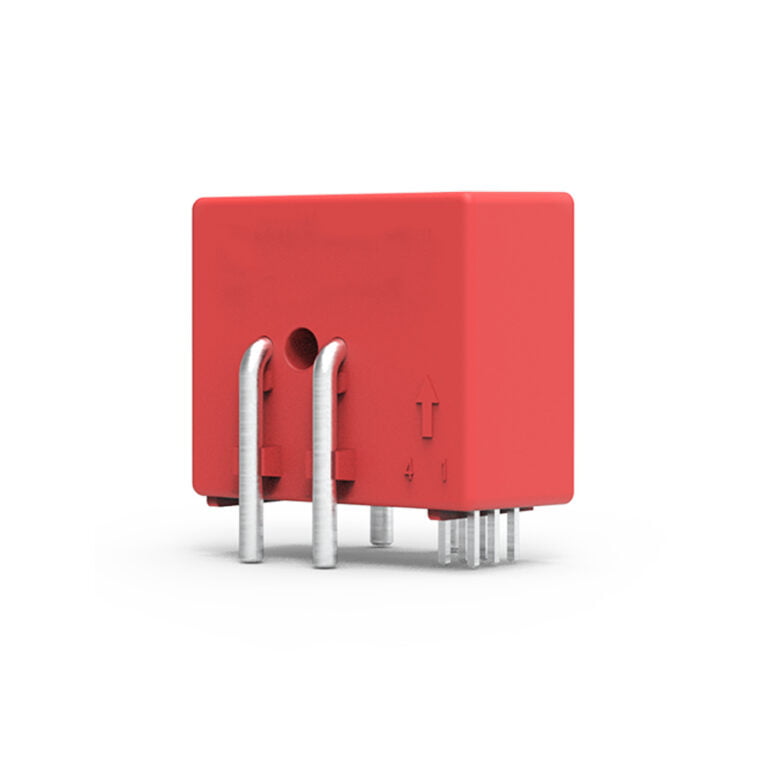

Introducing our cutting-edge DC contactors designed specifically for electric vehicle charging stations. Engineered with precision and reliability in mind, our DC contactors serve as the crucial link between the power source and the vehicle’s charging system. With features such as high-voltage capability, low power consumption, and rapid response times, our contactors ensure seamless and efficient power transfer during the charging process. Whether you’re designing a new charging station or upgrading an existing one, our DC contactors provide the performance and durability you need to deliver fast and reliable charging for electric vehicles.

DC contactor is one of the key components in DC charging pile. It is mainly used to control the output switch of DC charging pile to achieve the transmission and disconnection of electric energy. DC contactor has the characteristics of fast response, high reliability and low power consumption, which can ensure the safe operation of the charging pile. DC contactors are equipped in the middle of the charging battery system software and inverter power supply of electric vehicles.

First of all, the use of the occasion and the control circuit of the operating parameters have a comprehensive understanding of the example of the control power, operating voltage, current, operating frequency, operating system, operating circuit parameters and environmental conditions, etc. to understand. Then from a variety of series of contactors to determine the choice of contactor models and specifications suitable for its purpose.

When it comes to choosing a DC contactor, we generally look at a few key aspects. Current rating: Choose a contactor with a current rating higher than the maximum current you expect to carry. Physical Size: Consider the physical size of the contactor and make sure it fits in the space you have available. Load Type: Consider the type of load you are switching.

Introducing our high-performance circuit breakers meticulously crafted for integration within electric vehicle charging stations. Engineered to manage electrical currents with precision and reliability, our circuit breakers are the backbone of safety and functionality within the charging infrastructure. With rapid response times and robust construction, our circuit breakers effectively isolate faults and prevent potential electrical hazards, ensuring the smooth operation of charging stations under varying load conditions.

Whether it’s for residential, commercial, or public charging installations, our circuit breakers offer unparalleled protection and peace of mind, making them indispensable components for any charging station project. Upgrade your charging infrastructure with our cutting-edge circuit breakers and elevate the reliability and safety of your electric vehicle charging network.

Leakage circuit breaker, is a protection of leakage of electrical equipment, when the current in the power supply, more than the maximum current value set in advance, leakage circuit breaker will automatically disconnect, play a role in protecting the power supply, so as not to bring unnecessary safety accidents. In the leakage circuit breaker wiring diagram, there is a zero line, fire line, no leakage under the circumstances, the fire line and the zero line in the opposite direction, the current is equal, when there is a leakage of electricity, it will produce magnetic force, the current is not equal, so that the leakage circuit breaker will be disconnected, to achieve the role of protection.

The main function of the earth leakage circuit breaker is that when a person occurs leakage or electric shock accident, the earth leakage circuit breaker device will immediately cut off the power supply, to protect people’s safety, to prevent the occurrence of electric shock accident.

most of breakers divided into type A, type AC, type B, the most common are type A and type B,

AC type leakage protector: AC type leakage protector is developed and designed for industrial frequency sinusoidal leakage current, which can reliably protect against sudden and slowly rising sinusoidal leakage current.

A-type leakage protector: A-type leakage protector and AC-type leakage protector are basically the same in working principle (measuring the leakage value through zero sequence current transformer), only the magnetic characteristics of the transformer are improved, ① in addition to sinusoidal leakage signal can be reliably protected, ② it can also be reliably protected against pulsating DC component of the leakage signal. In electric vehicle charging pile, this type of product is applied more.

Type B earth leakage protector: In addition to ensuring disconnection like the type F earth leakage protector, the type B earth leakage protector can also ensure disconnection under the following currents. ① sinusoidal AC residual current of 1000Hz and below; ② AC residual current superimposed on smooth DC residual current; ③ pulsating DC residual current superimposed on smooth DC residual current; ④ pulsating DC residual current generated by two-phase or multi-phase rectifier circuit; ⑤ smooth DC residual current. And it has nothing to do with the polarity and the sudden appearance or slow rise of residual current.

Type B has more protection and is relatively safer, but correspondingly more costly

Circuit breakers for charging pile are generally divided into MCB, RCBO, RCCB, and over-under-voltage switch, according to the actual charging pile function needs to choose the appropriate circuit breaker,

RCBO is Residual Current Circuit Breaker with Overcurrent Protection,RCBO is the most versatile, with short-circuit + overload + leakage, three kinds of protective functions, the main function of the RCBO is to ensure protection against earth fault currents, overloads and short circuit currents.

MCB miniature circuit breaker is an electromagnetic device used to automatically break a circuit when the current flowing through it exceeds a set value. The MCB can also be turned on and off like a regular switch if desired. These devices are rated for 220 volts for DC power and 240/415 for AC power, including varying short-circuit current capabilities.MCBs perform a variety of functions, such as local control switches, overload protection devices for specific appliances or equipment, and disconnect switches to prevent errors.

RCCB: Residual Current Circuit Breaker with Overcurrent Protection. without overcurrent protection, also known as leakage switch.

1, the nature of different: MCB is the construction of electrical terminal power distribution device cited in the most widely used in a terminal protection appliances, RCBO is to prevent the occurrence of human body in the low-voltage lines or leakage of electricity caused by fire, explosion of a switching appliances, RCCB is used in the equipment leakage faults as well as a fatal risk of personal electric shock protection.

2, the characteristics of different: RCCB has the function of leakage current detection and judgement, and does not have to cut off and turn on the main circuit function of the leakage protection device. rcbo can quickly action, cut off the accident power supply, to avoid the expansion of the accident, to protect the person, the safety of the equipment. mcb by the operating mechanism, contacts, protection devices (various off-trigger), extinguish the arc of the system and so on.

Hey, I’m the author of this post, I entered EV charging field from 2012,In the past 11 years, we have rich experience for ev charging accessorries. if you plan to build your own stations, welcome to discuss with us.

Thanks for your interest, your inquiry will be responded within 24 hours.